- Palghar, Maharashtra

- +91-9322157397

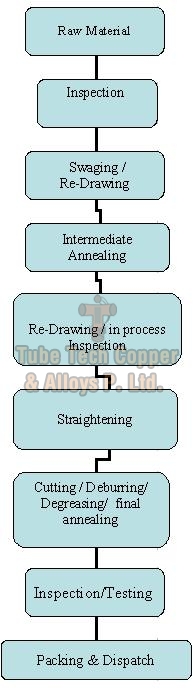

Manufacturing Process

Mother Tubes are procured from reputed manufacturers and are subjected to a thorough chemical analysis along with rigorous visual checks. The best quality mother tubes are then cold drawn on the draw benches.

Drawing involves pulling the hollow tube through a series of tungsten carbide dies of gradually decreasing diameters. Before each step of the drawing process, the tube is pointed at one end to fit through the next smaller die. Before drawing a stationery tapered plug mandrel is placed inside the tube. As the tube is drawn on linear draw benches, the mandrel and die act together to reduce both the tubes outside diameter and its wall thickness. The mandrel also makes the tubes inside surface smoother.

The tube is annealed in an annealing furnace as and when required by the given standard to make it suitable for the intended application. The straight tubes are passed through a series of straightening rolls before the final cutting operation to make it perfectly cut to the size. The soft annealed coils are wounded on the automated coilers. The samples of the tubes are checked at regular intervals during the entire manufacturing process to ensure their adherence to the desired parameters.

Finally, the tube is cleaned to remove any traces of drawing lubricants or other contaminations. Samples randomly drawn from the finished tubes are analyzed to ensure that it meets all requirements of size, wall thickness and quality as required under the applicable standards and customers requirement.

The finished plain tubes then undergo various chemical & mechanical tests as per the Specification / Customers requirements followed by marking and packing.

The tubes intended for further operations like Finning, Sleeve making, U Tube making, Bending, PVC coating are taken for further processing.

Contact Us

Tube Tech Copper & Alloys Pvt. Ltd.

37, Dandekar Industrial Estate, Old Satpati Road,, Palghar, Maharashtra - 401404, India

E-mail : ajit.tubetech@gmail.com