- Palghar, Maharashtra

- +91-9322157397

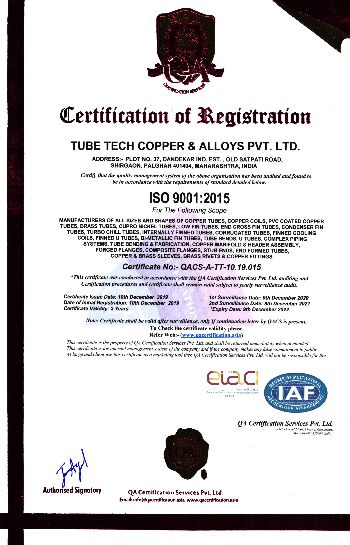

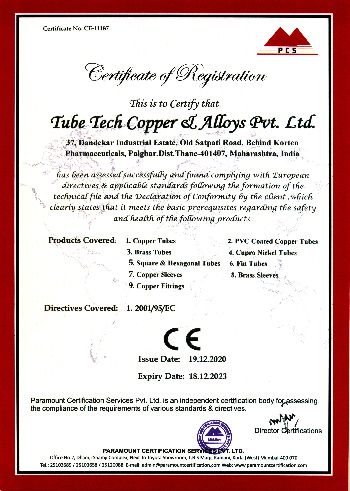

Quality & Certifications

Quality Control : It is the stringent regime of quality controls and procedures established at Tube Tech that gives its products the critical advantage in the industry. Strict process requirements and continuous monitoring throughout the production process minimizes the range of possible deviations in the final output. The works have been equipped with reliable testing and measuring equipment for destructive and non destructive testing. Quality : Quality has brought prosperity to Tube Tech. High product quality is an absolute priority for us and this constitutes a competitive advantage as it sets us apart from our competitors and hence makes a significant contribution towards securing and extending our market position. A determination to settle for nothing less than excellence is the foundation on which our company operates. Our stringent quality practices ensure that every product meets the industry's highest production standards. The products and services we offer not only meet the quality requirements of our customers but actually exceed them.

Quality Assurance : Quality Assurance System implemented at Tube Tech covers all production stages right from the raw material, re-drawing, annealing, till the final product is ready for dispatch. The elements of the quality assurance system correspond to the requirements of national and international standards, as well as customers own Quality Assurance requirements. The Quality control department is independent of manufacturing shop. All tests are carried out by trained quality personnel in compliance with the guidelines of the Quality Assurance System. Depending upon the intended application and technical delivery conditions or customers specifications, a variety of specific tests can be carried out to ensure that highest quality standards are maintained. Also, at the end of this meticulously uncompromising quality checks.

Quality Assurance Plan

| Process | Characteristics to be checked | Measuring Instruments | Quantum to be Checked |

| Raw Material / Mother Tube Inspection | Dimensions | Micro Meter | Random Sampling |

| Appearance | Visual | Random Sampling | |

| Swaging | Swage degree & Length | Visual | Random Sampling |

| Drawing / Intermediate Cutting | Dimensions | Micro Meter | Random Sampling |

| Surface / Length | Visual / Measuring Tape | Random Sampling | |

| Intermediate Annealing | Draw ability | Visual | Random Sampling |

| Straightening | Dimensions | Micro Meter | Random Sampling |

| Straightness | Visual & Measurement | Random Sampling | |

| Finish Cutting | Length | Measuring Tape | 100.00% |

| Deburring | Burrs on ends | Visual | 100.00% |

| Inspection | Dimension | Micro Meter | 100.00% |

| Length | Measuring Tape | 100.00% | |

| Surface | Visual | 100.00% | |

| Annealing | Temperature | Thermo Couple | Lot Wise |

| Speed | Speed Controller | Lot Wise | |

| Final Inspection & Testing | Dimensions | Micrometer & Measuring Tape | 100.00% |

| Leakage | Hydrostatic / Pneumatic Testing M/c | Random Sampling | |

| Physical & Mechanical Test | UTM, Hardness Tester Etc. | Random Sampling | |

| Packing | Marking & Packing | As Per Customer Requirement | 100.00% |

Contact Us

Tube Tech Copper & Alloys Pvt. Ltd.

37, Dandekar Industrial Estate, Old Satpati Road,, Palghar, Maharashtra - 401404, India

E-mail : ajit.tubetech@gmail.com